Dynamic torque inspection technology

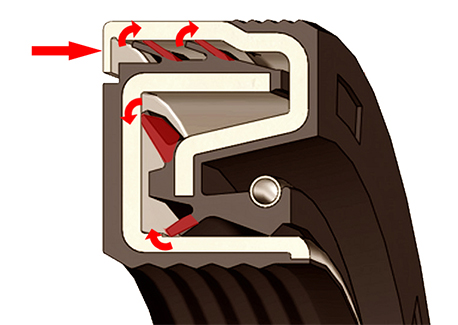

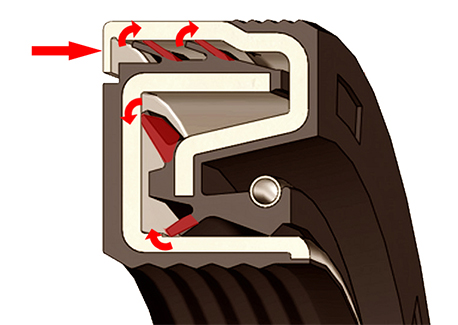

The Agri-hub is working in a severe operation environment which full of dust and mud; this requires the hub has a better

sealing structure. In order to meet the rigorous sealing requirements, we general use multi-lip sealing. The lips of the

multi-lip sealing can effectively form an air chamber to effectively block the mud and dust from outside.

What is the relationship between sealing and torque?

The torque of hub is from two main parts, the torque of hub itself and the torque of the sealing. Under certain locking force, the rotational torque

variation of the hub is very small; the amount of change is less than 0.1Nm. Most torque is from the sealing. The sealing lip is design according

to actual need. After the sealing assembled it will produce a certain amount of interference α, while generating a reasonable torque α Nm, it can

make the sealing structure in a reasonable state and efficient.

|

However in the actual situation, the manufacturing tolerances of the

hub sealing inner and outer rings will cause them have different axial

offset β (shown in red) after the assembly, which causes the

interference α of sealing lip become larger or smaller while delivering

torque αNm becomes larger or smaller. Interference α becomes smaller,

the barrier effect of dust will greatly weaken; interference α becomes

larger, the rotation of hub will increase lip friction and increase the heat,

so the lip wear rapidly. Furthermore, due to the moment αNm increases

excessively will cause the locking of the hub.

|

|

Dynamic torque inspection technology

CSELITE developed dynamic torque detection technology can detect α Nm of torque hub to determine whether the seal assembly is in a

reasonable range, to maximal ensure the effectiveness of the sealing system.

● High precision sensor

For accuracy of measurement, the sensor must maintain

excellent sensitivity in the state long-term measurements;

the sensor needs to amplify a weak pulse signal and real-time

display on the meter correctly. The samplingtime of the

sensor is also an important part,CSELITE through a large

number of actual comparison tests,weeliminates these

unstable dates in the beginning and end of the test to ensure

the accuracy of the measured values.

The precision of the mechanical parts are also crucial.Thanks

to the machining capacity of CSELITE, theframe portion of

the testing equipment has a highdimensional accuracy and

high concentricity.

|

|

|

● Multi-Position Measurement

In our industry, the torque inspection is generally sampling method,

but to ensure maximum reliability of the sealing structure of the hub,

we must use the full inspection. In that case, the efficiency of the

measurement largely restricted the rhythm of production. CSELITE

use four-position measurement simultaneously, which largely reduce

measurement time. Four-simultaneous measurement must ensure the

consistency of hydraulic and pneumatic systems in operation.

|

| ● Automatic data collection

For measured torque values, the system will automatically

measure the real-time data and displayed on the torque tester;

the torque detection software will map out the torque curve.

After the end of the measurement system automatically saves

the data to ensuretraceability of the measurement data.

|

|

|

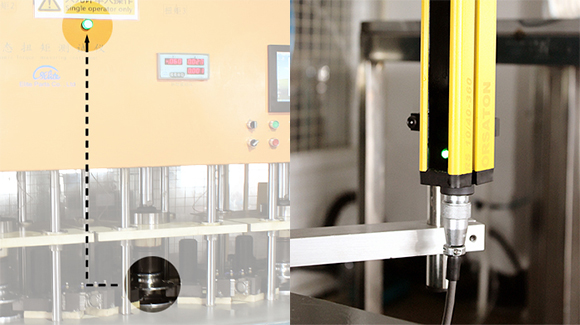

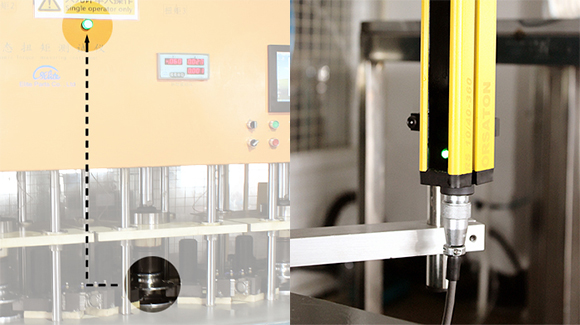

● Protection equipment

In order to protect the safety of the operator and the sensor structure,

CSELITE use electromagnetic induction and grating sensor for

protection devices. In the course of running dynamic torque

inspection, the grating sensor protection device continuously detects

whether an object is close, and will promptly stops to protect the

safety of operators.

|

|

Electromagnetic protection system will detect the placement

of the work-piece, if the placement is not in place then the

magnetic switch cannot be turned on, the panel light is off,

the measurement program can not start.

|

|