|

|

|

|

|

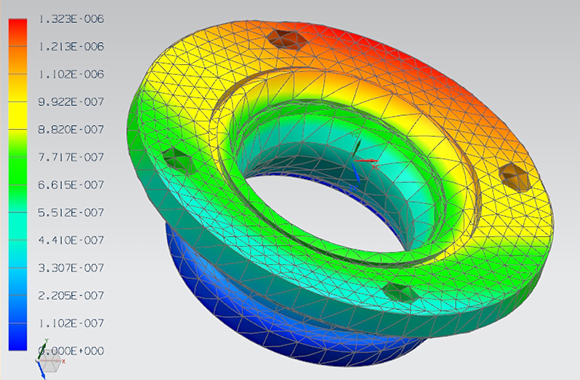

Optimized design The FEA technology is used to optimize the hub parameter design, and |

|

|

|

|

|

| Electroplating appearance All exterior surfaces are plated to effectively prevent rain, chemical |

|

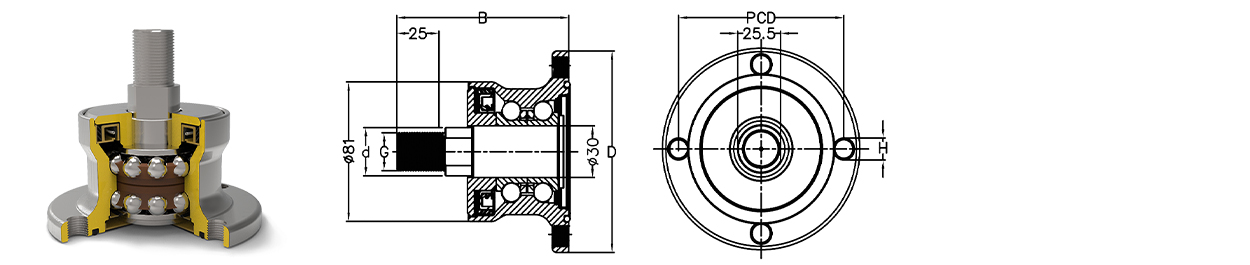

Technical parameter

| Designation | D | d | B | B1 | G | PCD | H | C | OEM No. |

| - | mm | mm | mm | mm | mm | mm | mm | mm | - |

| AH-30A-01 | 117 | - | 60 | - | No shaft | 98 | 4-M12x1.25 | - | SKF BAA-0003 Vaderstad 470974/481460/440488 |

| AH-30A-04 | 117 | 28 | 102 | 25 | M22x1.5 | 98 | 4-M12x1.25 | 25.5 | SKF BAA-0004/BAA-0023 Gregoire Besson 9031.40.12 |

| AH-30A-05 | 117 | 28 | 102 | 25 | M22x1.5 | 98 | 5-M12x1.25 | 25.5 | SKF BAA-0012 |

| AH-30A-06 | 117 | 28 | 102 | 25 | M22x1.5 | 98 | 6-M12x1.25 | 25.5 | SKF BAA-0006 |

| AH-30A-07 | 117 | 28 | 106 | 25 | M24x2 | 98 | 6-M12x1.25 | 25.5 | SKF BAA-0013 |

| AH-30A-08 | 117 | 30 | 97.5 | 22 | M24x1.5 | 100 | 6-M10x1.25 | 27 | LEMKEN 5554512 FKL IL50-100/6T-M24.R |

| AH-30A-09 | 117 | 30 | 97.5 | 22 | M24x1.5L | 100 | 6-M10x1.25 | 27 | LEMKEN 5554513 FKL IL50-100/6T-M24.L |

| AH-30A-11 | 117 | 28 | 102 | 25 | M24x2 | 98 | 4-M12x1.25 | 25.5 | SKF BAA-0005 |

| Designation | D | d | B | G | PCD | H | OEM No. |

| - | mm | mm | mm | mm | mm | mm | - |

| AH-30E-01 | 117 | - | 60 | No shaft | 98 | 4-M12x1.25 | SKF BAA-0003 Vaderstad 470974/481460/440488 |

| AH-30E-02 | 117 | - | 60 | No shaft | 98 | 5-M12x1.25 | |

| AH-30E-03 | 117 | 28 | 60 | No shaft | 98 | 4-M12x1.25 | SKF BAA-0003A Vaderstad 152271 |

| AH-30E-04 | 117 | 28 | 102 | M22x1.5 | 98 | 4-M10x1.25 | SKF BAA-0004/BAA-0023 Gregoire Besson 9031.40.12 |

| AH-30E-05 | 117 | 28 | 102 | M24x2 | 98 | 6-M12x1.25 | SKF BAA-0005 |

| AH-30E-06 | 117 | 28 | 102 | M22x1.5 | 98 | 6-M12x1.25 | SKF BAA-0006 |

| AH-30E-07 | 117 | 28 | 106 | M24x2 | 98 | 6-M12x1.25 | SKF BAA-0013 |

| AH-30E-08 | 117 | 28 | 102 | M24x2 | 98 | 4-M12x1.25 | SKF BAA-0009 |

| AH-30E-09 | 117 | 28 | 102 | M22x1.5 | 98 | 5-M12x1.25 | SKF BAA-0012 |