|

|

|

|

|

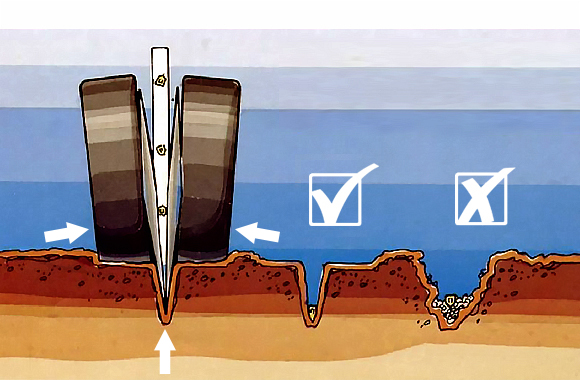

The stable bearing capacity Because the working state of the opener disc is tilted, the bearing |

|

|

|

|

|

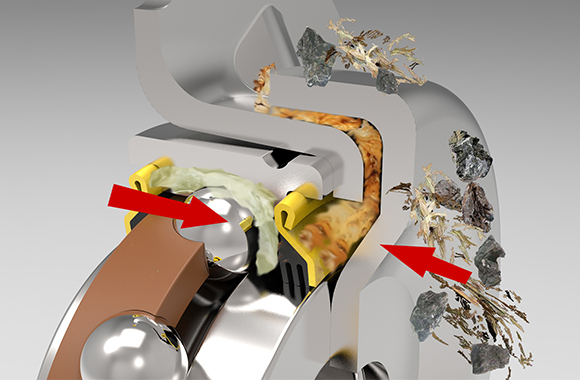

| Corrosion resistant surface Modern planters carry out both seeding and fertilization, including |

|

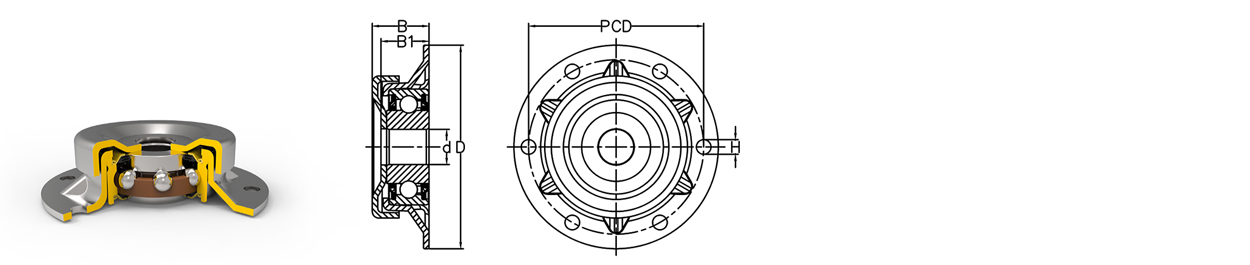

Technical parameter

| Designation | D | d | B | B1 | PCD | H | OEM No. |

| - | mm | mm | mm | mm | mm | mm | - |

| AH-16A-01 | 93.3 | 16.13 | 25.9 | 21.9 | 80 | 6-6.7 | GREAT PLAINS 404-121S |

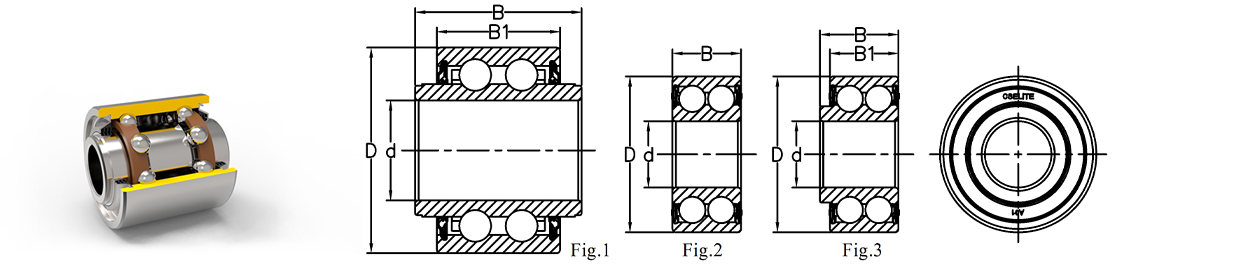

| Designation | Type | D | d | B | B1 | OEM No. |

| - | - | mm | mm | mm | mm | - |

| AB-5203A2RS-01 | Fig.1 | 40 | 16.195 | 43.88 | 38.93 | JOHN DEERE AN212132 CASE 324461A1 KINZE GA6171 GREAT PLAINS 822-170C KUHN 81101640 MONOSEM 7140A |

| AB-3204A2RS-01 | Fig.2 | 47 | 20 | 20.638 | - | MONOSEM 7014A INA 3204-BD-XL-2HRS-TVH PEER 5204-2RS |

| AB-3204T2RS-01 | Fig.3 | 47 | 20 | 25.2 | 21.9 | SEMEATO F-110390 PEER 5204-KP52-R-A116 / 5204KP52-SP6 |

| AB-5206KPP3-01 | Fig.1 | 62 | 30.15 | 50 | 37 | GREAT PLAINS 822-215C KINZE GA8603 / GA8641 PEER 5206KPP3 |

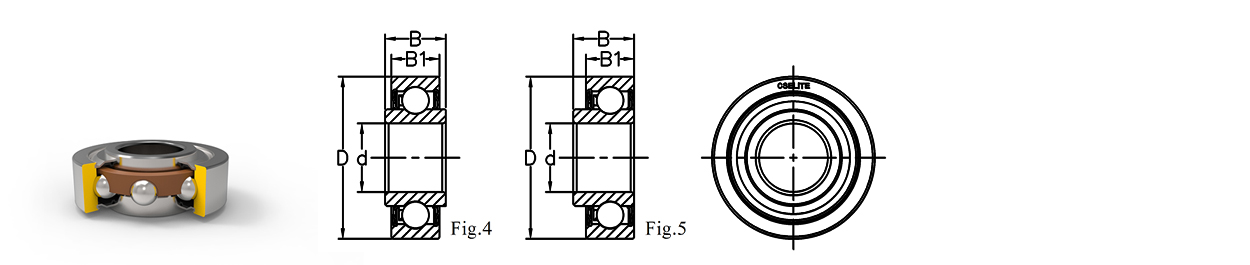

| AB-203KRR-AH02 | Fig.4 | 40 | 16.256 | 18.288 | 12 | JOHN DEERE AA82881 / AN100425 / AN142670 / AN281357 / JD 9214 NEW HOLLAND 66553 GREAT PLAINS 822-095C CASE 149261C91 / F16246 GEHL 520117 |

| AB-203KRR5-01 | Fig.4 | 40 | 13.081 | 18.288 | 12 | LEMKEN 3199369 PEER BB203KRR5 TIMKEN BB203KRR5 |

| AB-204KRR-01 | Fig.4 | 47 | 20 | 17.7 | 14 | KVERNELAND AC671871 FAG 204-XL-KRR |

| AB-204PY3-01 | Fig.5 | 45.225 | 16.053 | 18.669 | 15.494 | PEER 204PY3 / BB204-PF3-R-A453 |

| AB-205KRP2-01 | Fig.5 | 52 | 19.202 | 21.107 | 15 | JOHN DEERE A27002 / B30418 MARLISS 702020 SUNFLOWER SNDR30005 CASE 1337998C1 INA 205KRP2 TIMKEN 205RRAN PEER 205KRP2 |

| AB-AA205DD-01 | Fig.4 | 53.086 | 16.13 | 19.43 | 18.288 | GREAT PLAINS 188-001V JOHN DEERE AA205DD KRAUSE 40-172 |