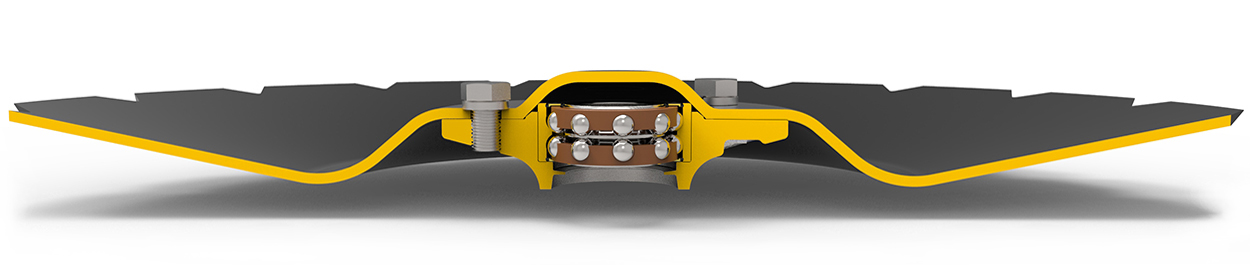

| Fertilizer disc hub Pneumatic seed drill is increasingly valued by farmers because they can complete seedbed preparation, leveling, fertilization, sowing and soil compaction, and pneumatic planters can effectively reduce the number of previous cultivation and reduce soil compaction, in high-speed working conditions can provide reliable seeding results. Because of the complex structure of the pneumatic seeder, it contains many independent working areas, and each area uses different bearings in order to achieve different functions, which undoubtedly increases the cost of development, procurement and maintenance for equipment manufacturers and end users. Therefore, CSELITE has introduced a new type of seeder which can be used in different working conditions. |

|

Meet all needs

From the core working parts in the pneumatic planer such as the soil leveling disc, the fertilization disc, the

seeding disc, to the single part such as the marker, each component has different load and sealing performance

on the bearing, and the requirements for each component Perform detailed analysis, balance the trade-offs

between different parameters, and match different external sealing components to ensure stable operation of

the hub on the required components.

|

|

Soil leveling The pneumatic seeder usually seeds directly on the ploughed |

|

The use of fertilizer disc for chemical fertilizer delivery requires |

|

|

The bearings on the marker are often overlooked, but for us, any |

| Coating surface Thanks to CSELITE's special electroplating coating process, after |

|

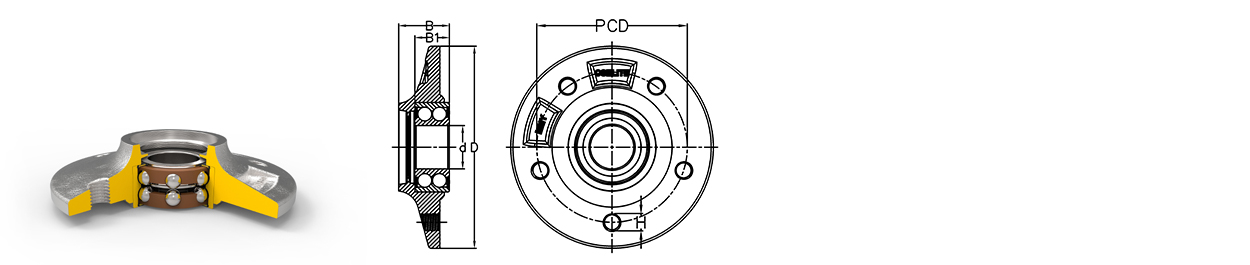

Technical parameter

| Designation | D | d | B | B1 | PCD | H | OEM No. |

| - | mm | mm | mm | mm | mm | mm | - |

| AH-30D-01 | 140 | 30 | 35 | 23.8 | 104 | 5-M12 | Vaderstad 420832 |