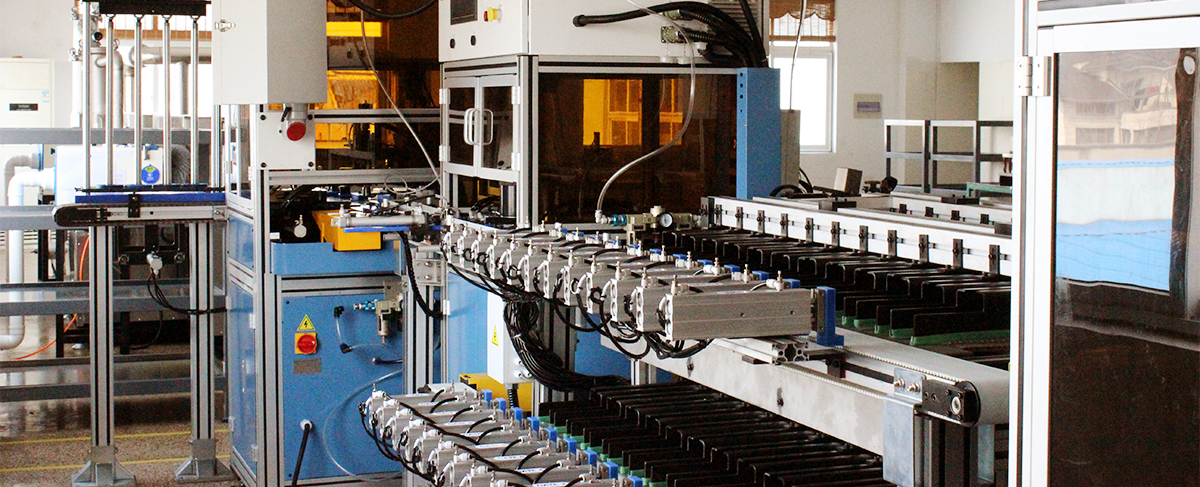

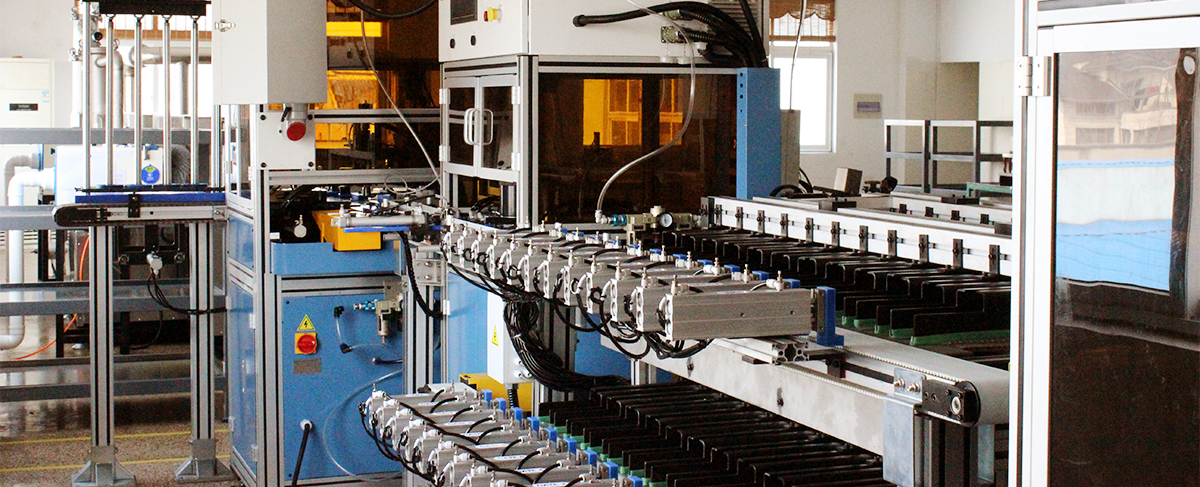

Bearing automatic matching system

The axial clearance is an important factor, which affect the bearing’s service life, working temperature and vibration. Therefore,

the stableness of axial clearance is an important point for hub matching. Introduce the automatic matching system in the hub

assembly can significantly increase the success tare and efficiency in hub matching.

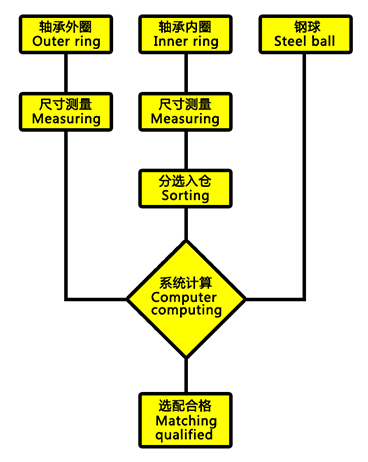

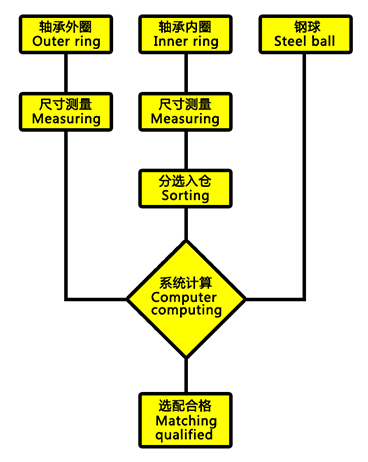

The principle of automatic matching system

Bearing automatic matching system is to automatically

measure the hub inner ring on the production line and

send to storage bin in accordance with the tolerance.

After measure the outer ring, the system will calculate

and pick the most appropriate inner ring, outer ring,

bearing ball and combine them to reach the set

clearance.

|

|

|

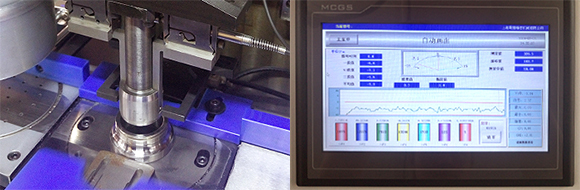

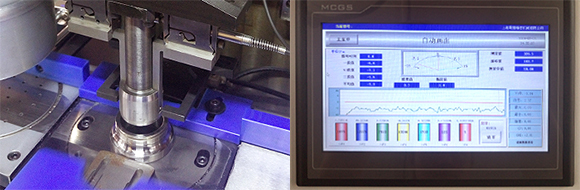

●Feeding and inner hole inspection

CSELITE automatic matching system use automatic feeding, the

operator simply use stick to gather the inner ring and put on the

feeder. The inner diameter directly affects the use and assembly

of the hub, so we inspect every product. The measuring probe

rotates and moves up and down to measure the roundness and

coning of each and every inner ring. The system storage and

analysis the measurement date automatically. The measuring

probe will automatically calibration after it reached a

predetermined dumber of measurements.

|

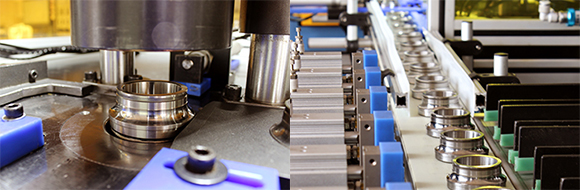

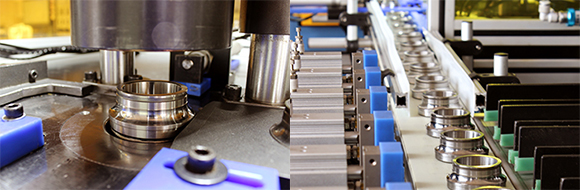

●Measuring and sorting of the inner ring

Sorting the inner ring is measure it through a special measuring

device to simulate the inner ring in the assembled state. System

gather many factors, inner diameter of grooves, the groove

position, groove curvature and so on, to calculate a relative

value, which will send to outer ring sorting system. After

measuring, the inner ring will transfer in to corresponding

storage bin and defective products will be picked out.

|

|

|

●Measuring and sorting of the outer ring

Similar to eh inner ring measuring, outer ring is measure through a

special measuring device to simulate the inner ring in the assembled

stat, and then calculate the relative value. According to the specific

matching algorithm, the system selects the most appropriate of the

inner ring and bearing ball to match with outer ring, and notify the

operator by LEDs.

|

|

Automatic matching system is a complete operating system,

which has precision measuring system, real-time data

transmission and visual interface. Compared to the traditional

manual sorting and matching, the automaticmatching system

has a higher efficiency and qualified rate, which greatly

reduces the labor intensity. And the matching qualified rate is

round 99.8%.

|

|