CSELITE sealing system

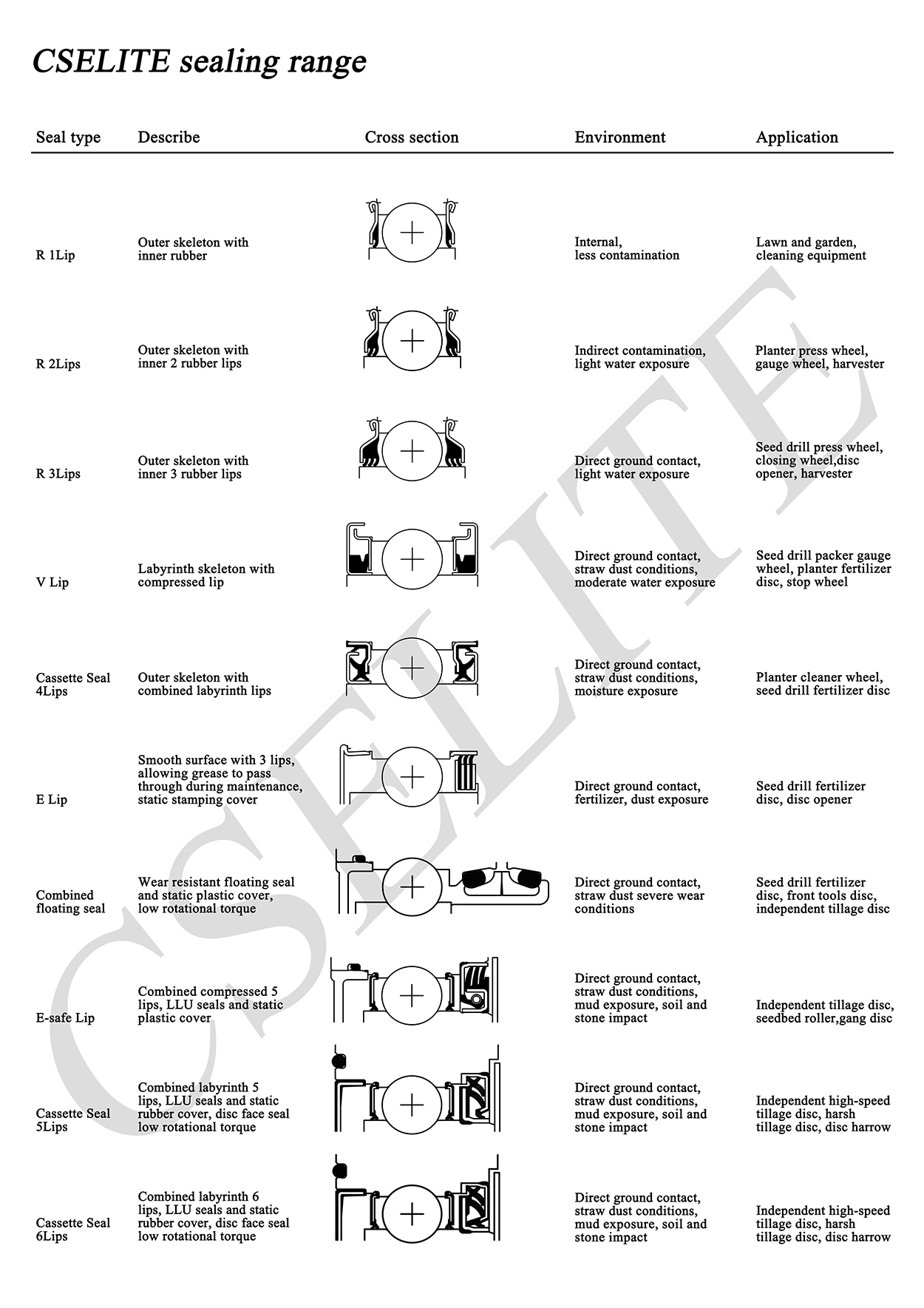

Bearings are one of the most important parts of modern agricultural machinery, and their working status is often related to the normal operation of the equipment. However, due to the diversity of the use environment and the non-standard product structure, general sealing methods cannot be accurately applied to agricultural bearings and hub. For example, the high-speed rotation of the forage harvester, the dust environment of the vibrating screen of the harvester, the impact and mud of soil tillage machinery, the low-torque rotation of the planter, different working environment need to choose suitable sealing methods, which requires the bearing manufacturer to have a perfect sealing system to ensure.

|

According to our long-term experience, about 78% of the failure of |

|

A complete sealing system

From garden mowing machinery to municipal cleaning machinery, from soil tillage to seedbed leveling, from precision

sowing to crop harvest, CSELITE sealing system always ensures stable operation of your equipment, reduces maintenance

and maintenance costs, and improves fuel economy.

If you need to customize the product, our technical engineers will help you to develop the appropriate sealing system according to the actual working situation.

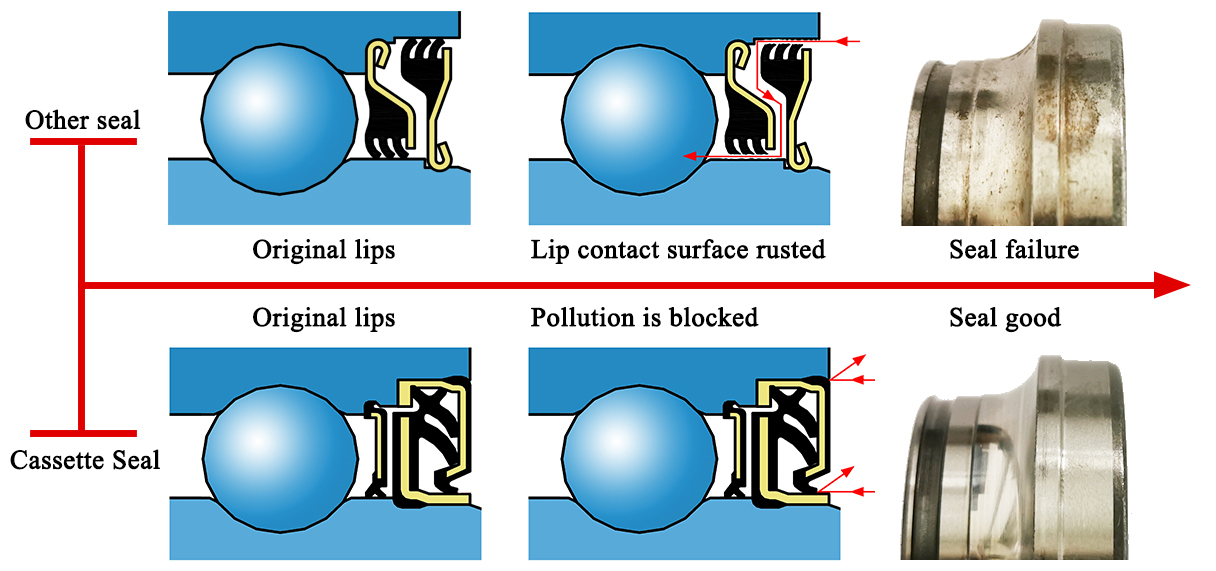

In many cases, multi lip R seal is a good solution, it can help the product in a faster speed to isolate external pollution.

However, in the heavy pollution environment, such as soil tillage in autumn, the high temperature and high humidity

environment will cause rust on the inner and outer ring surface contacting with the lip, the metal corrosion will make

the contact surface become rough, the lip will accelerate the wear, and the worn lip will accelerate the degree of corrosion,

resulting in a vicious cycle, and eventually bearing failure. CSELITE long-term sealing experience suggests that the cassette

seal should be used in the low-speed harsh farming environment. The inner lip of CSELITE cassette seal is labyrinth

distribution, and the lip and internal lubrication surface friction to avoid the lip wear caused by external corrosion and

improve the service life of bearing.

|

|

Details are also very important Compared with the seal size used by other manufacturers, |

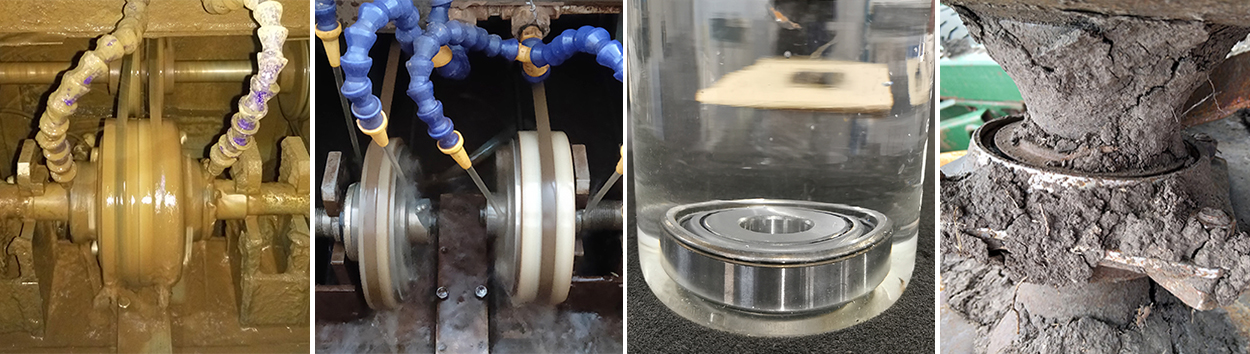

Various tests ensure quality

Through repeated laboratory tests under extreme conditions, the field test results of several agricultural production cycles

can be simulated in a very short time. Various sealing systems are tested day and night in harsh testing machines to simulate

various use conditions of agricultural machinery, which means that the sealing performance of each batch of products can be

quickly verified. Many different technical solutions can be validated at the project development stage, which also means

faster development cycle and faster product delivery. At the same time, we also keep close communication with agricultural

equipment manufacturers and farms for a long time, and finally verify the sealing system through field test.

For a long time, CSELITE has provided reliable products for agricultural and garden machinery. One of the reasons is that it is beneficial to our continuous exploration of product sealing. These researches are long-term and require a lot of manpower and material resources. However, we always firmly believe that these efforts will eventually be rewarded. It will be reflected in our products, improve its performance and benefit our customers.